Model DGB paper cake tray forming machine for cupcake

Product Description

#detail_decorate_root .magic-0{border-bottom-style:solid;border-bottom-color:#aaaaac;font-family:Roboto;font-size:18px;color:#000;background-color:#b3b2b2;font-style:normal;border-bottom-width:2px;padding-top:8px;padding-bottom:4px}#detail_decorate_root .magic-1{width:750px}#detail_decorate_root .magic-2{overflow:hidden;width:750px;height:400px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-3{margin-top:0;margin-left:0;width:750px;height:400px}#detail_decorate_root .magic-4{width:300px;display:flex;flex-direction:column;margin-right:4px;margin-left:0}#detail_decorate_root .magic-5{font-size:18px}#detail_decorate_root .magic-6{width:446px}#detail_decorate_root .magic-7{overflow:hidden;width:446px;height:286.2472248493278px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-8{margin-top:0;margin-left:0;width:447px;height:286px}#detail_decorate_root .magic-9{overflow:hidden;width:446px;height:304.05278213716105px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-10{margin-top:0;margin-left:0;width:475px;height:304px}#detail_decorate_root .magic-11{width:300px;display:flex;flex-direction:column;margin-right:0;margin-left:4px}#detail_decorate_root .magic-12{overflow:hidden;width:446px;height:350.7667113680154px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-13{margin-top:0;margin-left:0;width:548px;height:350px}#detail_decorate_root .magic-14{overflow:hidden;width:446px;height:393.4357037770081px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-15{margin-top:2.3786666666666667px;margin-left:-8.325333333333333px;width:447px;height:284px}#detail_decorate_root .magic-16{vertical-align:top}#detail_decorate_root .magic-17{vertical-align:top;display:inline-block;padding-right:4px;width:50%;box-sizing:border-box;margin-bottom:-4px;padding-left:0;margin-top:-4px}#detail_decorate_root .magic-18{vertical-align:top;padding-bottom:4px;box-sizing:border-box;padding-top:4px}#detail_decorate_root .magic-19{width:375px;height:372.78709055876686px;overflow:hidden}#detail_decorate_root .magic-20{position:relative;left:0;top:0;width:375px;height:375px}#detail_decorate_root .magic-21{vertical-align:top;display:inline-block;padding-right:4px;width:50%;box-sizing:border-box;margin-bottom:-4px;padding-left:0;margin-top:-4px;margin-left:-3px}#detail_decorate_root .magic-22{width:364px;border-collapse:collapse}#detail_decorate_root .magic-23{min-height:18px;padding:5px 10px;width:133px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-24{font-family:inherit;font-size:inherit;font-style:inherit;font-variant-ligatures:inherit;font-variant-caps:inherit}#detail_decorate_root .magic-25{min-height:18px;padding:5px 10px;width:199px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-26{min-height:18px;padding:5px 10px;width:133.4px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-27{min-height:18px;padding:5px 10px;width:198.8px;min-height:18px;box-sizing:content-box}#detail_decorate_root .magic-28{vertical-align:top;display:block;padding-right:4px;box-sizing:border-box;padding-left:4px}#detail_decorate_root .magic-29{padding:0;margin:0;white-space:pre-wrap;font-size:14px}#detail_decorate_root .magic-30{overflow:hidden;width:247.33333333333334px;height:152.72833333333335px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-31{margin-top:0;margin-left:0;width:247px;height:152px}#detail_decorate_root .magic-32{overflow:hidden;width:247.33333333333334px;height:152.20512820512823px;margin-top:0;margin-bottom:0;margin-left:4px;margin-right:0}#detail_decorate_root .magic-33{margin-bottom:10px;overflow:hidden}#detail_decorate_root .magic-34{overflow:hidden;width:750px;height:400px;margin-top:0;margin-bottom:4px;margin-left:0;margin-right:0}#detail_decorate_root .magic-35{overflow:hidden;width:373px;height:186.5px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-36{margin-top:0;margin-left:0;width:373px;height:186.5px}#detail_decorate_root .magic-37{overflow:hidden;width:373px;height:186px;margin-top:0;margin-bottom:0;margin-left:4px;margin-right:0}#detail_decorate_root .magic-38{overflow:hidden;width:373px;height:400px;margin-top:0;margin-bottom:0;margin-left:0;margin-right:0}#detail_decorate_root .magic-39{margin-top:0;margin-left:0;width:373px;height:400px}#detail_decorate_root .magic-40{overflow:hidden;width:373px;height:400px;margin-top:0;margin-bottom:0;margin-left:4px;margin-right:0} Product Description  Detailed Images

Detailed Images

Paper feeding section DGB is the newest design which is popular in domestic and abroad. Machine with steady body frame which is constructed by 2cm

thickness iron plate, looks more strong and professional

Paper molding section The paper products will be delivered into the mold section (up and lower mold) which is controlled by PLC, it is detected by two

Photoelectric sensors, after molding, two air pipe will blow the plate off the mold.

Box collecting section The paper products will be delivered into the mold section (up and lower mold) which is controlled by PLC, it is detected by two

Photoelectric sensors, after molding, the robot arm will collect the box.

Phneumatic section

Two fast cylinder working sections with high pressure, one for molding another for collect the finished box. All controlled by PLC Product Presentation

Certificate 产品优势能说明用文案Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.3张证书图片

Related Products Company Introduction Bonjee Machinery, the maker of automatic machinery for paper plate and take away box. Pingyang Bonjee Machinery Co., Ltd is a professional manufacturer of all types of food box automatic forming machine, disposable paper plate automatic making machine, integrating development and production together. Our export company is Wenzhou Unitely Imp and Exp Co., Ltd. Our main products include all paper product related machinery. Our company was established in 2006, we have many years of history in the machinery, and we have patent. We located near Ruian, enjoy very convenient transportation. Our company promises: reasonable prices, short production time and satisfactory after-sales service, we hope to cooperate with more customers for mutual development and benefits, also welcome potential buyers to contact and visit us.

Related Products Company Introduction Bonjee Machinery, the maker of automatic machinery for paper plate and take away box. Pingyang Bonjee Machinery Co., Ltd is a professional manufacturer of all types of food box automatic forming machine, disposable paper plate automatic making machine, integrating development and production together. Our export company is Wenzhou Unitely Imp and Exp Co., Ltd. Our main products include all paper product related machinery. Our company was established in 2006, we have many years of history in the machinery, and we have patent. We located near Ruian, enjoy very convenient transportation. Our company promises: reasonable prices, short production time and satisfactory after-sales service, we hope to cooperate with more customers for mutual development and benefits, also welcome potential buyers to contact and visit us.

Packing&Shipping

Packing&Shipping

FAQ FAQ

FAQ FAQ

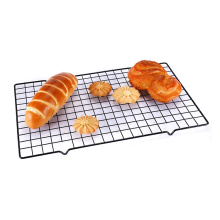

Q1. What Kinds Of Box Can Be Made By The Machine ?

PE coated paper

Q2. What Is The Packing Way Of The Machine?

Usual , With wooden cases packing.

Q3. What Is The Machine Delivery Time ?

As usual, 35 days shippment after received your deposits.

Q4. How About The Machine Guarantee?

One year. During this period, any parts damaged caused by machineself, the seller will repair/replace the spare parts for free. After one year, the seller will supply the spare parts to buyers as the cost. The machine service is all around the machine life.

Q5. What About The Machine Installation And Training ?

If customer request, we will send our technician to install and train operation, but all costs should be covered by buyer. (

including getting visa, 2-way air tickets, food. Hotel. Local traffic, translator, salarys ).

Q6.What Is The Terms Of Payment ?

By 100%T/T , 30% of deposits should be paid in advanced, then 70% of balance should be paid before shippment. or IL/C at sight, both are ok .

Q7. What About The Whole Produce Line For Bending Straw Making?

The whole produce line include the printing machine, slitting machine, paper straw forming machine, packing machine , any interested ,welcome to ask me freely.

Welcome to contact with me freely or send me the inquiry if you are interested in our machine. Contact us if you need more details on paper cake tray forming machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about paper cake tray forming machine、paper cake tray forming machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Detailed Images

Detailed Images Paper feeding section DGB is the newest design which is popular in domestic and abroad. Machine with steady body frame which is constructed by 2cm

thickness iron plate, looks more strong and professional

Paper molding section The paper products will be delivered into the mold section (up and lower mold) which is controlled by PLC, it is detected by two

Photoelectric sensors, after molding, two air pipe will blow the plate off the mold.

Box collecting section The paper products will be delivered into the mold section (up and lower mold) which is controlled by PLC, it is detected by two

Photoelectric sensors, after molding, the robot arm will collect the box.

Phneumatic section

Two fast cylinder working sections with high pressure, one for molding another for collect the finished box. All controlled by PLC Product Presentation

Product Name | BJ-DGB full automatic cake paper cup forming machine |

Suitable material | 100-400gsm PE coated paper |

Production speed | 80-120pcs/min (depend on plate shape and size) |

Blank paper size | 190mm x 190mm |

Total power | 3kw |

Overall dimension | 1500 x 1700 x 1900 mm |

Power source | 380V/220V, 50HZ |

Related Products Company Introduction Bonjee Machinery, the maker of automatic machinery for paper plate and take away box. Pingyang Bonjee Machinery Co., Ltd is a professional manufacturer of all types of food box automatic forming machine, disposable paper plate automatic making machine, integrating development and production together. Our export company is Wenzhou Unitely Imp and Exp Co., Ltd. Our main products include all paper product related machinery. Our company was established in 2006, we have many years of history in the machinery, and we have patent. We located near Ruian, enjoy very convenient transportation. Our company promises: reasonable prices, short production time and satisfactory after-sales service, we hope to cooperate with more customers for mutual development and benefits, also welcome potential buyers to contact and visit us.

Related Products Company Introduction Bonjee Machinery, the maker of automatic machinery for paper plate and take away box. Pingyang Bonjee Machinery Co., Ltd is a professional manufacturer of all types of food box automatic forming machine, disposable paper plate automatic making machine, integrating development and production together. Our export company is Wenzhou Unitely Imp and Exp Co., Ltd. Our main products include all paper product related machinery. Our company was established in 2006, we have many years of history in the machinery, and we have patent. We located near Ruian, enjoy very convenient transportation. Our company promises: reasonable prices, short production time and satisfactory after-sales service, we hope to cooperate with more customers for mutual development and benefits, also welcome potential buyers to contact and visit us.

Packing&Shipping

Packing&Shipping

FAQ FAQ

FAQ FAQQ1. What Kinds Of Box Can Be Made By The Machine ?

PE coated paper

Q2. What Is The Packing Way Of The Machine?

Usual , With wooden cases packing.

Q3. What Is The Machine Delivery Time ?

As usual, 35 days shippment after received your deposits.

Q4. How About The Machine Guarantee?

One year. During this period, any parts damaged caused by machineself, the seller will repair/replace the spare parts for free. After one year, the seller will supply the spare parts to buyers as the cost. The machine service is all around the machine life.

Q5. What About The Machine Installation And Training ?

If customer request, we will send our technician to install and train operation, but all costs should be covered by buyer. (

including getting visa, 2-way air tickets, food. Hotel. Local traffic, translator, salarys ).

Q6.What Is The Terms Of Payment ?

By 100%T/T , 30% of deposits should be paid in advanced, then 70% of balance should be paid before shippment. or IL/C at sight, both are ok .

Q7. What About The Whole Produce Line For Bending Straw Making?

The whole produce line include the printing machine, slitting machine, paper straw forming machine, packing machine , any interested ,welcome to ask me freely.

Welcome to contact with me freely or send me the inquiry if you are interested in our machine. Contact us if you need more details on paper cake tray forming machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about paper cake tray forming machine、paper cake tray forming machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : paper cake tray making machine

Premium Related Products

Other Products

Hot Products

Aluminum Offet Printing PlateSample Free Offset Printing PlateSensitive CTP Printing PlateSharp Dots Offset Print Thermal PlatesHigh Resolution Ctcp PlatesAluminum Offset Printing Ctcp PlatesHigh Quality Positive PS PlateCTP PlateCTP PlateKord Size Machine PS PlatePositive High Quality Long Run CtcpHigh Quality Long Run CtcpDeveloperDeveloping PowderHigh Quality Positive PS Plate in Blue CoatingHigh Quality A Grade Positive Blue Coating PS Plate